Damage report

The Engine wiring loom on Chestnut has three parts.

- The Control Panel on the Pod next to the throttle,

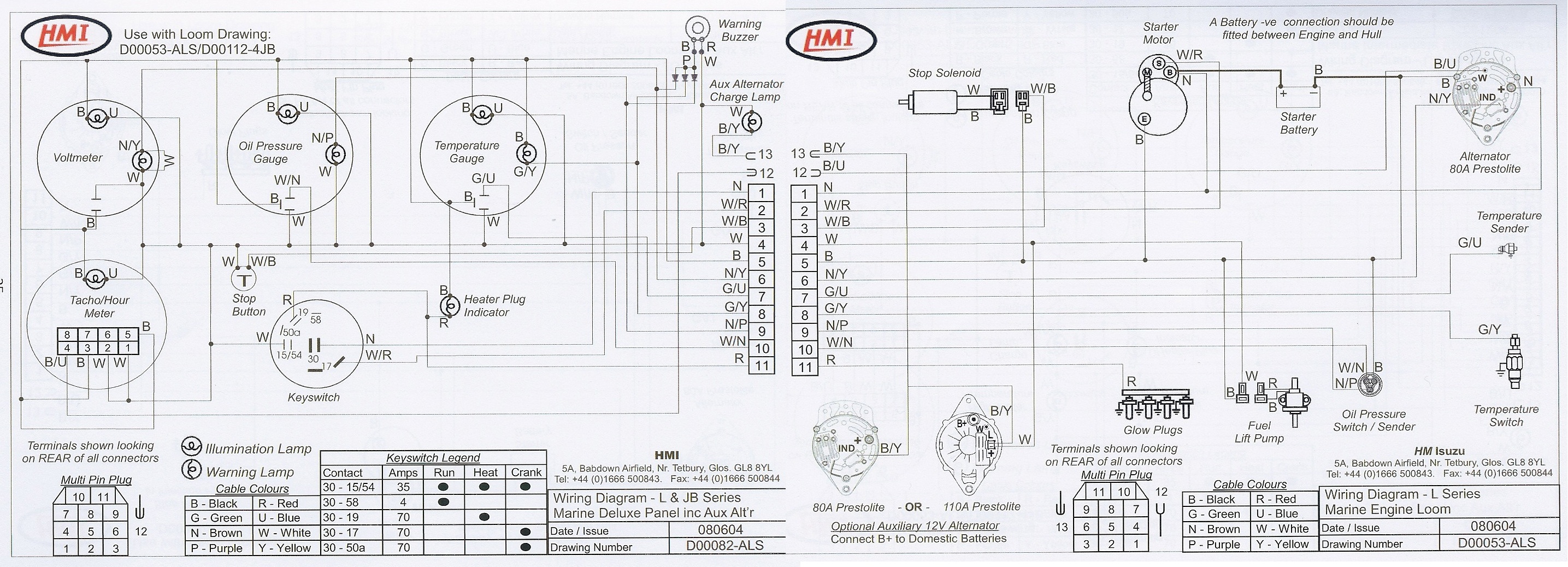

takes all the wires from the ignition switch, warning lamps, tacho, and gauges and connects them down a short loom to a 13-way plug about 250mm from the panel.

takes all the wires from the ignition switch, warning lamps, tacho, and gauges and connects them down a short loom to a 13-way plug about 250mm from the panel. - A two metre extension cable has a socket at the top end that is connected to the Control Panel plug and carries the electrics down through the engine bay to near the engine where it ends on another 13-way plug.

- A socket that attaches to the bottom extension plug takes the 13 wires from the control panel and distributes them all over the engine: to alternators, starter motors, oil temperature and pressure gauges, coolant temperature, glow plugs, fuel pump, and others.

The whole of this third section had melted way beyond repair, and the socket was damaged. Luckily, the extension, and its plug, had one wire that required re-insulating.

The Post-mortem

Once I got to study the Engine wiring diagram there were obvious design issues:

For a start there is a note at the top right that says: “A Battery -ve connection should be fitted between Engine and Hull”. This was NOT done. If this HAD been fitted none of this incident would have occurred.

There are no fuses on the diagram. I don’t think they were considered important.

In practice there was a single fuse, a slow-blow 40A, in the brown wire next to the Starter motor that fed the entire Engine Electrical system.

Most of the wires in the loom were rated for 16Amps, a couple were rated at 25A and four at 33A. One of the 33A wires fed the Engine Glow-plugs that take 50Amps initially but drops to 35A after about 5 seconds. This is why the fuse is slow-blow, if it were quick to operate the glow plugs would blow the fuse every time the engine was started! As it was most of the loom’s 16Amp wires were protected by a single 40Amp fuse that means most of the wires would melt and catch fire before the fuse blew.

When the Domestic alternator first broke down, I removed the thick cable that charged the battery but left in place the lamp and sense wires. This was a mistake. The lamp and sense wires on an alternator should be connected to the battery that the Alternator is charging, but in this case they were connected to the Engine Starter battery, not the Domestic Bank.

It was the sense wire, still connected to the faulty Alternator that took enough current through its 16Amp rated wire to melt the loom while not blowing the 40Amp fuse.